The Football (Soccer Ball)

4. The functions of the ball casing

The casing is the most exposed component of a football. It should be largely abrasion-resistant, evenly round and keep shape. Its properties should remain stable under all game and weather conditions. This demanding catalogue of requirements presented a particularly motivating challenge for inventors.

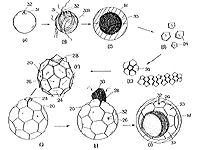

We will briefly present the components composing most of today's football casings and the required manufacturing steps, based on US patent application 5 772 545 A1 (Figure 8).

(A) shows a bladder ball 31 with mounted valve stem 32. A strengthened glue-coated thread 331 (eg. made of nylon) is evenly wound around this bladder ball until it forms a web layer (B, C) which is heated and molten to obtain strengthened bladder 30. (D) shows the polygonal panels 24, cut out of leather or synthetic leather, which are machine-sewn together (E) in such a way that the seams are on the outer side (F). The ball cover is turned right side out using remaining inlet opening 28 (G); the reinforced bladder 30 is inserted as shown by (H) and the valve stem is glued to valve hole 26 provided in one of the polygonal panels. Opening 28 is sewn together by hand. The ball is then ready to be inflated.

Sometimes a reinforced panel is provided opposite the valve segment for counterbalancing purposes (DE 196 24 020 C1).

Recent developments include a ball with panels for weight control arrangement that also serve to strengthen the outer casing (US 2016/0 101 326 A1).

A new manufacturing process aims to ensure that the football has stable play properties over a wide temperature range (WO 2017/067 564 A1).

| Publikationsnummer | Jahr | Titel | Kurzbeschreibung |

|---|---|---|---|

| US 5 772 545 A | 1996 | Sportsball and manufacturing method thereof | Herstellungsprozess eines Fußballs |

| DE 196 24 020 C1 | 1996 | Spielball und Verfahren zu dessen Herstellung | Austarierung des Störeinflusses des Ventils durch ein Ausgleichselement , das geometrisch gegenüber in der Fußballhülle platziert wird |

| US 2016/0 101 326 A1 | 2016 | Sportsball with Weight Control arrangement | |

| WO 2017/067 564 A1 | 2017 | Ball, in particular a football, and method for producing same |

4.1 The seams

Stable sewing of the individual ball panels presents a particular challenge as the seams are subject to high stress. They should not be visible to avoid wear and roughness of the ball surface.

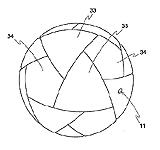

Sewing techniques include the early staggered double seams (DE-PS 354 758), seams on fabric linings of individual panels covered by adhesive tapes (DE-PS 363 800), various combined adhesive and stitching solutions (DE-PS 366 073) and loop seams (GB 384 570 A, Figure 7), and the recent self-shrinking threads (US 5 752 890 A) which should provide for an enhanced durability of the seams.

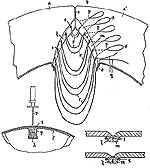

Figure 9 taken from GB 384 570 A shows the sewing process very clearly. The "loop" stitching of the panels (a [top] and I, m[bottom right] ) of a ball casing is made by means of thread q, and the panel seams are additionally glue-sealed.

Recent developments include a manufacturing process in which the seams of the ball are covered by heating a layer of heat-active adhesive. (DE 10 2016 121 751 A1).

| Publikationsnummer | Jahr | Titel | Kurzbeschreibung |

|---|---|---|---|

| DE 10 2016 121 751 A1 | 2017 | Sportball und Verfahren zum Herstellen des Sportballs | |

| US 5 752 890 A | 1998 | Ball for ball game and method for manufacturing the same | Selbst schrumpfende Fäden im Einsatz bei der Vernähung einer Ballhülle |

| GB 384 570 A | 1932 | A ball for games | Schlaufen-Vernähung einer Fußballhülle |

| DE-PS 366 073 | 1922 | Verfahren zur Herstellung äußerlich unsichtbarer Nahtverbindungen an Spielballhüllen | siehe Titel |

| DE-PS 363 800 | 1921 | Spielhülle mit verdeckten Nähten | siehe Titel |

| DE-PS 354 758 | 1920 | Naht zur Verbindung der Lederteile an Sportballhüllen | Vernähung einer Ballhülle mit versetzten Doppelnähten |

4.2 The component structure

Two of the above figures show that today's footballs usually consist of three or more layers or shells (cf. DE 43 39 677 A1, EP 0 598 542 A2).

This design has been adopted to optimise the spherical shape, increase durability and achieve better bounce of the ball, eg. through lower water uptake and adapted cushioning. Over the years, artificial leather and other synthetic materials have widely replaced genuine leather for manufacturing football casings (eg. proposed in GB 733 154 A as early as in 1951).

It is sometimes proposed to construct the ball from a solid core with construction elements extending from the solid core to the outside, forming the ball when fully assembled (US 2009/0 170 397 A1).

The new "tri-tech soccer ball" (US 2017/0 259 126 A1) has a multi-layered casing designed to improve the manufacturing process and play characteristics.

| Publikationsnummer | Jahr | Titel | Kurzbeschreibung |

|---|---|---|---|

| EP 0 598 542 A2 | 1993 | Inflatable sports ball | Mehrschichtenaufbau einer Fußballhülle |

| DE 43 39 677 A1 | 1993 | Verwendung eines Verbundstoffes zur Herstellung von Sportbällen | Mehrschichtenaufbau einer Fußballhülle |

| US 2009/0 170 397 A1 | 2009 | Ball assembly | |

| US 2017/0 259 126 A1 | 2017 | Methods of manufacturing of tri-tech soccer ball |

4.2.1 The carcass

The inflated bladder ball is usually bonded with a web layer made of fibres providing tensile strength. This layer provides stability to the bladder ball and prevents excessive inflating.

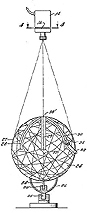

Textile-like materials are often used for this purpose (cf. DE-PS 480 658, fabric, 1927; US 3 219 347 A, 1927 (Figure 10) and US 3 405 018 A, nylon, 1961; US 4 333 648 A, nylon elastomer thread; WO 95/09034 A1 multi-layer nylon, 1995).

Depending on the desired properties, the other layers may include foam, latex or specifically developed elastic either for cushioning or for enhanced bounce capacity. This composite unit is usually bonded through vulcanisation or using adhesives. It is often referred to as the "carcass".

The final outer casing, which shows the typical panel structure, is either sewn as described above or laminated onto the carcass. This method has been increasingly used for about 15 years (eg. WO 2004/056 424 A1), although is has been known since 1913, according to DE DE - PS 281 587.Thermal bonding allows to obtain particularly smooth surfaces, since there are no seams and no bulges.

A current example: The "impact dissipating ball" consists of multiple layers, one of which serves as a cushioning interlayer to dissipate impact loads (EP 3 132 831 A1; also very similar: EP 3 162 413 A1).

| Publikationsnummer | Jahr | Titel | Kurzbeschreibung |

|---|---|---|---|

| WO 2004/056 424 A1 | 2002 | Ball for ball game and method for manufacturing the same | Aufkleben der Segmente der Außenhülle eines Fußballs |

| WO 95/09034 A1 | 1993 | Sports ball and method of manufacture of same | Verstärkung der Ballhülle durch mehrlagiges Nylon für größere Zugfestigkeit |

| US 4 333 648 | 1982 | Inflatable game ball | Verstärkung der Ballhülle durch ein Nylon-Elastomer-Gewebe |

| US 3 405 018 | 1961 | Method of making simulated seam reinforcing and rigidizing for air-inflated balls | Verstärkung der inneren Ballhülle mittels auf dieser aufgewickelten Nylonfäden |

| US 3 219 347 | 1961 | Air inflated ball with reinforced seams | Verstärkung der inneren Ballhülle mittels auf dieser aufgewickelten Nylonfäden |

| DE-PS 480 658 | 1927 | Nahtloser Fußball mit mehrlagiger, auf die Gasblase aufgeklebter Verstärkungshülle | siehe Titel |

| DE-PS 281 587 | 1913 | Lehrform zur Herstellung von Sportbällen aus einzelnen aneinandergeklebten Teilen | siehe Titel |

| EP 3 132 831 A1 | 2016 | Impact dissipating ball | |

| EP 3 162 413 A1 | 2016 | A multi-fuze gaming object |

4.2.2 Physical properties of the layers

The specific physical properties of the individual ball casing layers have recently been the subject matter of many patent applications. The focus has been partly on the tensile strength achieved through the individual components (eg. WO 95/09034 A1) and partly on improving elasticity to optimise bounce properties.

The desired bounce is often achieved by adding elastic hollow bodies to the synthetic intermediate layers of the casing. These provide for a sort of air cushion (DE 44 08 047 A1, DE 197 32 824 A1, DE 100 42 244 A1, WO 97/17109 A1). Other applications propose the creation of graded pore sizes within a specific layer (EP 0 385 872 A2), additional fleece padding (DE 43 39 677 A1) or use of a matrix material with embedded dimensionally stable, elastic blow-moulded parts (DE 197 58 546 A1).

Use of synthetic materials has some disadvantages too. Leather adapts comparatively well to the inner pressure created by an inflated bladder, ie. it has sufficient elasticity to expand and bulge. Many laminated synthetic materials are less well adapted and need to be specifically preformed and assembled.

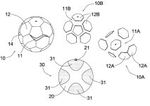

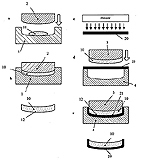

According to DE 102 55 092 A1 each individual panel is moulded to obtain the desired three-dimensional shape (Figure 11) which it ought to have when the ball is fully inflated. Several manufacturing steps are required for this purpose.

Backing material 10 is preformed in a press using mould 2, before being placed on a further mould 3 and laminated to pre-heated mouldable part 20; this composite piece is one of the panels that will form the outer casing of a football.

In order to achieve the same flight properties as with a sewn outer casing, the outer casing of the football (EP 3 067 100 A1) is formed by individual panels glued to a carcass whose gaps are provided with filling material.

| Publikationsnummer | Jahr | Titel | Kurzbeschreibung |

|---|---|---|---|

| EP 3 067 100 A1 | 2016 | Ball, in particular a soccer ball, and method of manufacturing a ball | |

| DE 102 55 092 A1 | 2002 | Verfahren zur Herstellung von Teilstücken eines Balls | Optimale Vorformung von Einzel-Kunststoffsegmenten für eine Ballhülle |

| DE 100 42 244 A1 | 2000 | Verbundmaterial für eine Ballhülle, insbesondere Fußballhülle | Geschlossenzelliger Kunststoffschaum als Polsterschicht einer Ballhülle |

| DE 197 58 546 A1 | 1997 | Fußball | Polsterschicht aus elastischen Festkörpern für eine Ballhülle |

| DE 197 32 824 A1 | 1997 | Fußball | Polsterschicht aus elastischen Hohlkörpern für eine Ballhülle |

| WO 97/17109 A1 | 1996 | A ball and a method of manufacturing a ball | Elastomer mit Hohlzellen als Polsterschicht in einer Ballhülle |

| WO 95/09034 A1 | 1993 | Sports ball and method of manufacture of same | Verstärkung der Ballhülle durch mehrlagiges Nylon für größere Zugfestigkeit |

| DE 44 08 047 A1 | 1994 | Ballhülle, insbesondere für Fußbälle | Luftpolsterschicht aus bläschenförmigen Kammern für eine Ballhülle |

| DE 43 39 677 A1 | 1993 | Verwendung eines Verbundstoffes zur Herstellung von Sportbällen | Vlies als Polsterschicht für eine Ballhülle |

| EP 0 385 872 A2 | 1990 | Ballons de sports ou de loisiers, comprenant unse couche externe en mousse à peau intégrale et leur obtention | Gradierte Porengrößen in einer Polsterschicht der Fußballhülle |

4.2.3 Perfect casings - for what purpose?

Many of the techniques and materials described above help to obtain a surface smoothness that is sometimes not desired in practice. When using nearly perfectly smooth footballs, players often complain about a lack of "football feeling" which they used to experience before.

This has somewhat reversed the previous trend towards ever smoother surfaces. Profile segments are sometimes arranged on the laminated panels. In addition to conferring the desired "feeling", they should provide for better ball control and enable the goal keeper to hold on to the ball more easily (DE 202 20 150 U1).

A specific football with an outer casing containing particles of expanded material (DE 10 2015 209 795 A1) is intended to improve abrasion resistance and tear resistance.

| Publikationsnummer | Jahr | Titel | Kurzbeschreibung |

|---|---|---|---|

| DE 10 2015 209 795 A1 | 2016 | Ball und Verfahren zu dessen Herstellung | |

| WO 2006/055 781 A1 | 2006 | Dimpled inflatable game balls | Fußball mit Strukturelementen auf der Oberfläche |

| DE 202 20 150 U1 | 2002 | Ballhülle, insbesondere für Fußbälle | Profilelemente auf der Ballhülle für eine bessere Ballkontrolle durch den Spieler |

4.3 Patterns and optical aspects

Nowadays, the ball casing also has an optical function. A specific football is being created (and marketed) for nearly any major football event. Individual surface designs are not only created by means of different colours and plastic films bearing designer elements which are laminated onto the ball casing (eg. made of polyurethane, cf. WO 95/09034 A1), but also by means of individual panel patterns.

From approx. WWI until the 1970 World Cup, footballs typically had the panel pattern shown in the above figure with the "lacing fork" of 1928. Since 1970, people have expected a football to show a black-and-white pattern composed of pentagonal and hexagonal panels.

However, there are many other alternatives to design the cover of a football using individual panels. Some examples are shown in the documents DE-PS 804 418, DE-GM 1 723 048, DE-GM 1 723 049, DE 44 34 751 A1, DE 700 67 84 U1, DE 195 34 144 A1, DE 195 35 636 A1 and DE 195 41 395 A1.

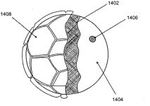

WO 01/83047 A1 presents a configuration made of triangular and pentagonal panels (Figure 12).

| Publication number | Year | Title | Brief description |

|---|---|---|---|

| WO 01/83047 A1 | 2000 | Ball for ball game and method for manufacturing the same | Ball cover composed of triangular and pentagonal panels |

| WO 95/09034 A1 | 1993 | Sports ball and method of manufacture of same | Polyurethane film bearing designer elements, laminated onto the ball casing |

| DE 195 41 395 A1 | 1995 | Ballhülle, insbesondere für Fußbälle | Football cover consisting of pentagonal and three-pointed star segments |

| DE 195 35 636 A1 | 1995 | Hohlkörper, Ball, Sportball, insbesondere Fußball , mit bevorzugt sphärischer bis ellipsoider Hülle nach Maßgabe kreisförmiger bis elliptischer Grundmuster | Hollow body, ball, sports ball, in particular football, preferably with spherical to ellipsoid casing determined by circular to elliptic basic patterns |

| DE 195 34 144 A1 | 1995 | Hohlkörper, Ball, Sportball, insbesondere Fußball, hergestellt aus ein bis fünf verschiedenen Polygon-Facettenformen nach einem Dreiecksgrundmuster | Hollow body, ball, sports ball, in particular football, composed of one to five different types of polygon facets based on a uniform triangular pattern |

| DE 44 34 751 A1 | 1994 | Ballhülle | Football cover consisting of triangular and elongated rhombus segments |

| DE 700 67 84 U1 | 1970 | Sportball | Football cover composed of pentagons and triangles |

| DE-GM 1 723 049 | 1956 | Hülle für Fuß- und andere Spielbälle | Football cover consisting of rectangular and pentagonal segments |

| DE-GM 1 723 048 | 1956 | Hülle für Fuß- und andere Spielbälle | Football cover consisting of bone shaped segments |

| DE-PS 804 418 | 1949 | Sportballhülle aus Zuschnittsgruppen | Typical football cover of the 1950s |