Shin Guards

The history of shin guards goes back to the 2nd half of the 19th century when the widely used cricket pads were introduced in football as leg protection. These pads greatly affected the freedom of movement and were hardly compatible with the increasing speed of the football game. For this reason, leg protection was reduced to the most sensitive parts of the front of the leg and, above all, the tibia. Many players discarded shin guards altogether in order to avoid bearing additional weight and getting cramps that were frequently caused by tightly laced shin guards.

Wearing shin guards is mandatory under today's football rules to prevent injuries. In response to the players' needs, innovations relating to shin guards focus in particular on weight reduction and flexible fastening solutions, which maintain freedom of leg movement, in addition to ongoing improvements relating to enhanced protection.

1. The development of shock absorbing materials

The core function of shin guards is to spread loads over wider areas, thus reducing the local impact force of kicks or blows. In the early days of football, metal, wooden or leather plates were used for this purpose, which were fastened to the players' legs. Very early it was proposed to pad the protective shell of shin guards with a soft inner layer, tightly fastened to the lower leg, so as to create a hollow between the rigid plate and the leg (DE 458 365).

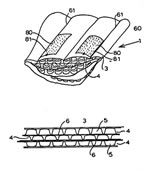

![]() Figure 1: Shin guard with shell (11) and cushioning layer (12) consisting of several fibre layers (DE 93 12 305 U1)

Figure 1: Shin guard with shell (11) and cushioning layer (12) consisting of several fibre layers (DE 93 12 305 U1)

Since the middle of the 1950s, shin guards have largely been made of hard thermoplastic shells, padded at the inside with a soft tissue or foam lining which may have an antimicrobial function. The padding may be attached to the shell by means of hook and loop fasteners.

The inner coating of the shin guard usually has good shock absorbing properties. Additionally, the still unequalled damping effect of air cushions is being used. Air cushions are provided either between the hard outer shell and a soft inner lining or by specific air inclusions provided in the interior of the foam coating. This concept is applied in a fairly recent example from the year 1995 (DE 295 00 630). Shin guards with honey-comb air-filled lining and custom-made protective socks with inflatable air chambers constitute interesting air cushion applications.

It is nowadays common practice to use synthetic viscoelastic materials, mainly complex compounds in a layer or foam structure, for shock absorbent inner cushioning linings. The shin guard presented in DE 93 12 305 U1, shown in Figure 1, consists of a shell (11) and a cushioning layer (12), composed of two fibre cover layers (15,16) and a vertically arranged monofil fibre layer (17), providing optimum flexibility of the shell under shear load.

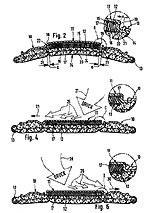

![]() Figure 2: Shin guard featuring several layers (4) of resilient and shock absorbing material forming a plurality of air pockets (5) (DE 27 03 538 U)

Figure 2: Shin guard featuring several layers (4) of resilient and shock absorbing material forming a plurality of air pockets (5) (DE 27 03 538 U)

Meanwhile, shells are no longer being made up of only one simple hard plastic material. Rather, they often consist of several layers of structured material with good cushioning properties (Figure 2).

Polymer materials based on ethylene vinyl acetate copolymer (EVA), that were developed in the 2nd half of the 20th century, have become very popular. These materials are also used for cushioning shoe soles. Likewise, manufacturers increasingly use materials that stiffen in response to shock and shear forces (so-called rheopectic or dilatant materials), such as viscous mixtures of polyborosiloxanes and lubricants that have been used ao. in bicycle seats.

Air inclusions are of specific importance since they allow to obtain excellent cushioning properties, in particular where a defined structure of the material can be achieved using modern synthetics.

The use of plastics allows to custom fit shin guards. Protective shells made of synthetic resin are moulded at the individual player's legs before curing, during the manufacturing process of the shin guards. Alternatively, it is possible to (once) custom fit a fully manufactured shin-guard subsequently by incorporating material that contracts irreversibly upon the application of heat.

Some shin guard designers tried to discard rigid protection components and merely incorporated a foam pad in a reinforced synthetic fabric, comparable to the knee and elbow pads widely used in other sports. Despite the high degree of free movement provided, this type of shin protection was not generally accepted.

Recently it was also proposed to use a gas-supported buffer cushion with tubes open on one side as insulating material (DE 10 2010 007 528 A1), which would also be suitable for goalkeeper gloves.

Players who had to suffer a few shin kicks in the heat of battle might be happy about the shin pads with replaceable, reusable inserts (US 2013/0 218 105 A1).

The US 2014/0 259 324 A1 shin guard is a protective impact shell consisting of two parts that are hinged together.

| Publication number | Year | Title | Brief description |

|---|---|---|---|

| WO 2007/036751 A2 | 2007 | Protective Lower Leg Garment | Shin guard with incorporated thermally sensitive material that contracts irreversibly upon the application of heat |

| US 6,701,529 B1 | 2004 | Smart Padding System Utilizing an Energy Absorbent Medium and Articles Made Therefrom | Rheopectic energy absorbent medium consisting of polyborosiloxanes and lubricants, stiffening in response to shock or shear forces |

| DE 100 10 182 A1 | 2000 | Viskose Kunststoffzusammensetzung | Improvements in shock absorbing ethylene vinyl acetate copolymer materials |

| JP 2001-070 495 AA | 1999 | Antimicrobial Shin Protector | Shin guard consisting of hard polyethylene shell and soft interior fabric coating with antimicrobial properties |

| DE 295 00 630 U1 | 1995 | Polstereinrichtung zum Schutz von Körperteilen bei Kollisionen | Gaiter-style shin guard with curved protective plates or rib-shaped protective elements with interior air cushion for shock absorption purposes (see US 5,671,478 A) |

| US 5,544,663 A | 1995 | Front-to-back and side-to-side custom-molded protective device | Custom-fitted multi-layer shin guard with rigid outer shell, flexible inner layer and intermediate layer made of shape retaining resin |

| DE 93 12 308 U1 | 1993 | Körperschützer, insbesondere Schienbeinschützer für Sportler | Gaiter-style shin guard with rigid shell and air cushion layer with honeycomb structure |

| DE 93 12 305 U1 | 1993 | Körperschützer, insbesondere Schienbeinschützer für Sportler | Gaiter-style shin guard with rigid shell and multi-layer fibre padding |

| DE 41 20 135 A1 | 1991 | Körperschützer, insbesondere Schienbeinschützer für Sportler | Shin guard with multi-layer compound fibre shell |

| US 5,274,846 A | 1991 | Cushion Having Multilayered Closed Cell Structure | see title |

| FR 2 600 900 B1 | 1991 | Dispositif de protection et/ou de maintien d'une partie d'un corps humain ou animal, notamment les jambes d'un joueur de football, et procede de realisation d'un tel dispositif | Method for custom fitting shin guards with resin shells by direct curing at the player's leg |

| DE 83 23 979 U1 | 1983 | Knie-, Ellenbogen-, Knöchel- oder Schienbeinschützer für Sportler | Shin guard made of soft fabric pads, without rigid plates |

| DE 32 25 355 A1 | 1982 | Gliedmassenschutz für Sportler, insbesondere Schienbeinschützer | Two-part shin guard with tight-fitting inner pad and rigid outer shell, attached by means of hook and loop fasteners which allow to adapt the position of the pad for better fit |

| DD 148 441 | 1980 | Schienbeinschutz aus Polyolefinschaum | Use of ethylene vinyl acetate copolymers (EVA) as cushioning materials for shin guards |

| DE 27 03 538 | 1977 | Körperschützer | Shin guard featuring several layers of resilient and shock absorbing material forming a plurality of air pockets |

| DE 7638546 | 1976 | Verletzungsschutz für Sportler, insbesondere Schienbeinschützer | Shin guard consisting of a rigid outer plastic shell and a soft inner padding layer, attached to each other |

| DE-OS 21 64 472 | 1971 | Beinschutz für Sportler | Sock-type shin guard with inflatable chambers |

| DE-GM 1 899 803 | 1964 | Schienbein-Schutzvorrichtung | Shin guard made of PVC with inner foam coating |

| DE-GM 1 843 552 | 1961 | Schienbeinschützer für Ballspiele | Shin guard consisting of rigid shell and two soft padding strips |

| GB 720,140 A | 1952 | Improvements in or relating to Shinguards | Shin guard consisting of two rigid sheets of different curvature, the space between the sheets being filled with shock absorbing material |

| DE-PS 458 365 | 1925 | Schienbeinschützer für Sportzwecke | Shin guard with outer curved steel plate and soft inner rubber layer, tightly fastened to the lower leg, so as to create a hollow between the rigid plate and the leg |