Football Footwear

2. The development of football shoes

2.1. Early concepts for weight reduction and increased freedom of foot movement

In Western Europe and in England, above all, players continued to wear rugged boot type footwear until the middle of the 20th century. Stable footwear with good grip was required to cope with bad weather and pitch conditions and soaking wet, heavy leather balls. In southern countries, by contrast, mainly in South America, it was possible to wear considerably lighter shoes. Due to lighter footwear, these countries developed a much faster, more athletic and sophisticated style of game.

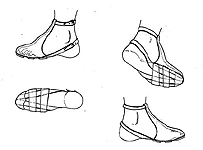

German patent literature from the 1920s did in fact include a proposal for an extremely light, sandal-type football shoe (Figure 2). Understandably, this type of shoe was not successful, since it was not suitable for bad weather conditions and did not protect the largely bared foot from injuries. Freedom of movement of the foot and ball feeling were enhanced by lower cuts, not going beyond the lacing at the upper instep, and by cutting out a section at the heels area, going below the ankle (Figure 3).

However, most of the patents filed in Europe before WWII concerned, above all, improved grip and stability of the sole (cf. section 3) while maintaining the ankle-high boot design.

Increasing internationalisation of football competitions after WWII and more frequent encounters of European and so-called "Latin" football styles forced Europeans to adopt more flexible and lighter cuts.

In Europe, interest began to focus on shoes meeting these requirements. Several patents were granted in Germany for inventions relating to this field in the early 1950s. As the weight of the shoe had been largely determined by the sole and the heavy toecap, innovations focused on abandoning the heavy cap and parts of the sole.

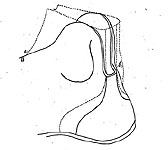

Typical innovations of that time included cushioned inlay soles to protect the foot from studs pressure or for raising the heels, use of lighter rubber materials for toe padding at the inside, springy inlay soles to ensure that the foot was flexibly embedded in spite of tight lacing, and use of flexible rubber-like materials for the collar (Figure 4).

In Western Europe and in England, above all, players continued to wear rugged boot type footwear until the middle of the 20th century. Stable footwear with good grip was required to cope with bad weather and pitch conditions and soaking wet, heavy leather balls. In southern countries, by contrast, mainly in South America, it was possible to wear considerably lighter shoes. Due to lighter footwear, these countries developed a much faster, more athletic and sophisticated style of game.

![]() Figure 3: Football boot with cut-out shaft for increasing free movement at the heels area (DE-PS 386 726)

Figure 3: Football boot with cut-out shaft for increasing free movement at the heels area (DE-PS 386 726)

German patent literature from the 1920s did in fact include a proposal for an extremely light, sandal-type football shoe (Figure 2). Understandably, this type of shoe was not successful, since it was not suitable for bad weather conditions and did not protect the largely bared foot from injuries. Freedom of movement of the foot and ball feeling were enhanced by lower cuts, not going beyond the lacing at the upper instep, and by cutting out a section at the heels area, going below the ankle (Figure 3).

However, most of the patents filed in Europe before WWII concerned, above all, improved grip and stability of the sole (cf. section 3) while maintaining the ankle-high boot design.

Increasing internationalisation of football competitions after WWII and more frequent encounters of European and so-called "Latin" football styles forced Europeans to adopt more flexible and lighter cuts.

![]() Figure 4: Use of flexible materials for the collar to increase freedom of foot movement (DE-PS 922573)

Figure 4: Use of flexible materials for the collar to increase freedom of foot movement (DE-PS 922573)

In Europe, interest began to focus on shoes meeting these requirements. Several patents were granted in Germany for inventions relating to this field in the early 1950s. As the weight of the shoe had been largely determined by the sole and the heavy toecap, innovations focused on abandoning the heavy cap and parts of the sole.

Typical innovations of that time included cushioned inlay soles to protect the foot from studs pressure or for raising the heels, use of lighter rubber materials for toe padding at the inside, springy inlay soles to ensure that the foot was flexibly embedded in spite of tight lacing, and use of flexible rubber-like materials for the collar (Figure 4).

| Publication number | Year | Title | Brief description |

|---|---|---|---|

| DE-PS 922 573 | 1953 | Sport-, insbesondere Fußballstiefel | Football boot with flexible soft collar for increased freedom of foot movement |

| DE-PS 816 511 | 1950 | Sportschuh für Fußballsport o. dgl. | Reinforced shoe tip with interior padding for increased stability and toe protection |

| DE-PS 816 510 | 1949 | Sportschuh, insbesondere für Eishockey- und Fußballsport | Football shoe with springy inlay for the foot bed for flexible, not too flat foot position in spite of tight lacing |

| DE-PS 804 072 | 1949 | Fußballstiefel und Verfahren zu seiner Herstellung | Plastic or leather plates incorporated in the outsole to counterbalance studs |

| DE-PS 800 365 | 1949 | Sportschuh, insbesondere Fußballschuh | Laced football shoe with attachable studs and insertion of a heel lift for better stability |

| DE-PS 386 726 | 1922 | Fußballstiefel | Football boot with cut-out shaft for increased freedom of foot movement |

| DE-PS 376 995 | 1922 | Sportschuhwerk | Light, sandal-type football shoe |

2.2. Football shoes

Low-cut design became increasingly popular over the years. At the 1954 World Cup, the German national team sported shoes whose collars ended below the ankles. This legendary shoe model, designed by Adi Dassler, was based on Dassler's running shoe which he had originally developed for track and field athletics. He adapted it to the special stability requirements of football and, above all, added exchangeable studs with adjustable height (cf. section 3).

The flat and dainty shoe design considerably increased the risk of injuries, especially in the ankle and Achilles tendon areas, but also at the instep and the tip. To prevent injuries, local reinforcing elements were later incorporated for targeted protection of these foot areas.

It was also attempted to further improve the stability of the shoe by similar measures, however with mostly unsatisfactory results. Most of these problems were only solved with the development of which were at the same time lightweight, weather-proof, sturdy and tear-proof, such as synthetic leather, polyamides eg. nylon, polyurethanes and polyesters. Combined with natural light materials such as viscose or cotton they allowed to create lightweight, comfortable and permanently stable football shoes. Since the early 1980s, wearing through of the upper was no longer a real problem even if the shoes were frequently used on hard courts.

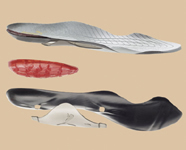

![]() Figure 5: Springy elastic inlay sole supporting the foot when kicking the ball, with additional cushioning element at the heels area (illustration of the inlay sole described in WO 02/00051 A1, copyright: PUMA)

Figure 5: Springy elastic inlay sole supporting the foot when kicking the ball, with additional cushioning element at the heels area (illustration of the inlay sole described in WO 02/00051 A1, copyright: PUMA)

One major challenge in shoe manufacturing still consists in creating a permanently stable adhesion of the upper to the sole. The optimum balance between shoe stability, foot protection and shoe weight seems to have been achieved nowadays. For this reason, recent developments relating to the upper concerned manufacturing techniques and, above all, the grip of the shoe surface for optimum ball handling (cf. section 4), or they concerned enhanced shoe comfort (cf. DE 34 41 624 for heat insulation) and optimum cushioning of the foot by means of springy elastic inlay soles (Figure 5). The revolutionary polyurethane, which had originally been used as a leather replacement, has gradually been replaced by more comfortable modern viscoelastic polymers.

A newer development "fuses" football socks and football shoes: An "improved football shoe", as described in DE 102014202432 A1, has an upper part made of knit fabrics with function-adapted areas to promote ball control and reduce the risk of twisting an ankle. US 2015/0101212 A1 also attaches particular importance to ankle protection.

The "modular shoe" DE 102015200523 has a sock-like outer shoe and should be particularly individually adaptable.

To this day, the major sporting goods manufacturers continue to compete for new optimization steps in the production of football shoes. A wealth of new patents shows that these efforts are being driven forward with great zeal and effort. The trend in the applications for industrial property rights currently is towards further weight reduction and the increased use of knitwear and knitting processes.

| Publication number | Year | Title | Brief description |

|---|---|---|---|

| WO 02/00051 A1 | 2001 | Als Zwischensohle, Innensohle oder Einlegesohle ausgebildete Sohle für einen Schuh und Schuh mit einer derartigen Sohle | Bendable springy elastic inlay sole |

| DE 39 24 360 A1 | 1989 | Sportschuh, insbesondere Fußballschuh | Football shoe with cushioning element incorporated in the heels area of the sole |

| DE 38 32 743 A1 | 1988 | Laufsohle mit dämpfender Zwischensohle | Compressible shock absorbing inlay sole with "tube system" |

| DE 34 41 624 A1 | 1984 | Sportschuh | Football shoe with internal heat reflecting layer for the winter season |

| DE 27 11 579 A1 | 1977 | Material mit lederähnlichen Eigenschaften und Verfahren zu seiner Herstellung | Leather-like material based on polyurethane with porous, waterproof, but water vapour permeable properties |

| DE-PS 2 107 447 | 1971 | Sportschuh mit angespritzter Laufsohle | Manufacturing of outsoles moulded onto the shoe upper, the sole consisting of a specific polyamide-based material, due to which the sole retains its shape while the material cures |

| DE-GM 1 886 440 | 1963 | Sportschuh | Football shoe with nylon coated cover of the laced opening, with additional padding in the middle part for foot protection purposes |

| DE-GM 1 868 954 | 1959 | Sportschuh | Football shoe with protective cap attached to the front part |

| DE-GM 1 797 088 | 1959 | Fußballschuh | Football shoe with nylon toe cap |

| DE-GM 1 794 640 | 1959 | Sportschuh, insbesondere Rennschuh oder Fußballstiefel | Football shoe with pad in the heels area provided with a felt or foam layer to protect the Achilles tendon |

| DE-PS 928 996 | 1952 | Fußballstiefel | Football half boot with cork reinforcements in the front part and laterally extended parts in the ankle area for shock protection |

| DE-PS 922 572 | 1952 | Fußballschuh | Football half-boot with cork instep plate to protect the foot and enhance shooting technique (see section 4.1) |

| DE-PS 816 967 | 1949 | Schuh und Verfahren zu seiner Herstellung | Method for manufacturing a running shoe, which constitutes a precursor of the football shoe |