Football Footwear

3. Soles

3.1. Studs, cleats and nubs

The most striking component of a football shoe is the sole. Depending on the playing surface, today's outsoles either feature six to eight studs (for best possible grip on soft and muddy turf), approx. 10 to 18 cleats (for dry turf or hard courts), or many nubs (for artificial turf). The distribution of the nubs on the sole can be arranged specifically to meet the individual requirements of the player's position. Special goalkeeper shoes, for example, have more studs or nubs on the outer region of the sole to provide increased stability before jumping. Shoes with special soles have even been developed for beach football.

| Publication number | Year | Title | Brief description |

|---|---|---|---|

| WO 2006/100447 A1 | 2006 | An Article of Footwear | Goalkeeper footwear with increased number of studs or nubs on the outer region of the sole |

| DE 44 17 563 A | 1995 | Fußballschuh | Special goalkeeper boot, provided with ground-engaging members on the outer area of the sole in addition to conventional nub arrangement |

| DE 30 32 268 C2 | 1980 | Aus elastischem Material bestehende Laufsohle | Shoe with rubber nub sole, the nubs being obliquely aligned in the ball, heel and ankle joint areas, and along the rim of the sole |

| DE 28 28 561 C3 | 1978 | Aus Gummi oder einem anderen Material mit gummielastischen Eigenschaften bestehende Laufsohle | Shoe with obliquely arranged nubs for even load distribution over the whole tread sole |

| DE 25 46 971 A1 | 1975 | Allwetter-Sportschuh, insbesondere Fußballschuh | Tread sole with thread sockets for attaching screw studs or blind plugs, to adapt the number of studs to the surface conditions |

| DE-GM 1 825 445 | 1960 | Sportschuh mit insbesondere aus Gummi bestehender Nockensohle | Cleat shoe, the number of cleats being reduced to 13 for enhanced grip |

| DE-GM 1 809 860 | 1959 | Sportschuh | Football shoe featuring 18 rubber cleats with reinforced necks |

| DE-PS 868 859 | 1950 | Fußballstiefel | Early football shoe with many small rubber nubs |

3.2. Utilisation of screw-in studs

The smaller the number of studs attached to the sole, the higher the torsional and shearing forces acting upon the individual stud. These forces occur when the player changes the direction abruptly which frequently occurs in the course of the game. Reliable fastening of the studs to the sole is particularly difficult if the shoe has only six studs.

The early football boots had studs nailed onto the sole. Later, studs were screwed onto the bottom of the shoes. As the socket threads of early shoe models were not accessible from the sole side, the tread sole had to be removed for changing these studs, and, as the sole was regularly damaged during the exchange procedure, the sole mostly had to be replaced too. Exchanging screw studs was a very cumbersome process which was carried out for repair purposes only.

German patent literature from the 1920s included first suggestions for easily exchangeable screw studs. DE 530 454, for example, suggested to fix several discs cut out of waste leather onto a base plate by means of metal pins and to fasten the plate by means of screws. This design provided at least for an inexpensive method to exchange the studs without damaging the sole. However, it was time-consuming and only meant for repair purposes.

The earlier patent DE 443 311 had proposed to nail leather strips provided with sockets for receiving studs onto the sole of a football boot. This method allowed to change studs without damaging the outsole. In addition, the easy and comparably fast stud change made it possible to adjust the stud height.

Even today, screwing in studs is the most widely used method for attaching replaceable studs. As an alternative, easily removable rib and slot or spring assemblies were proposed at an early stage. However, only recent developments of these types of assemblies are sufficiently stable. In addition they now allow to vary the height.

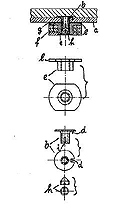

Proposals relating to the use of socket members secured to the sole were disclosed in US patent literature and a later German patent specification, which additionally proposed to use special inlay soles (Figure 6).

Nearly 30 years later, the highly sophisticated manufacturing of exchangeable screw studs with adjustable height fastened onto light and agile football shoes, guaranteeing uniform high traction due to fast adaptation to changing pitch conditions caused a sensation at the 1954 World Cup final (Figure 7).

| Publication number | Year | Title | Brief description |

|---|---|---|---|

| EP 1 446 029 B1 | 2006 | Article of Footwear with a replaceable ground-engaging member and method of attaching the ground-engaging member | Sports shoe with spring-loaded click mechanism for removable studs |

| US 2006/0130372 A1 | 2006 | Article of Footwear with Height Adjustable Cleat-Member | Attachable replacement cleat with variable height |

| DE 102 48 482 A1 | 2004 | Sohle und Verfahren zur Herstellung einer Sohle | Football shoe with locking mechanism for attaching studs |

| DE 102 41 153 B3 | 2004 | Stollen und Schuh | Shoe provided with studs having magnetically operable fastening means |

| DE 298 07 082 U1 | 1998 | Sohle für Sportschuh, insbesondere Rasensportschuh | Multi-purpose sport shoe with studs, fastened by means of a snap-locking arrangement and fixed in the locking position by an expanding core |

| DE 32 42 606 A1 | 1983 | Stollen für Sportschuhe, insbesondere Fußballschuhe | Sport shoe with studs, fixed by means of bayonet joints |

| DE 1 846 934 U | 1962 | Klemmbarer Auswechsel-Stollen für Sportschuhe | Sport shoe with studs, fixed by means of clamping locks |

| DE-PS 821 611 | 1950 | Leichtsportschuh und Verwendung einer Einlegesohle in ihm | Half-boot with light, flexible sole with attachable studs and cushioning inlay soles |

| DE-PS 530 454 | 1930 | Auswechselbarer Stollen für Fußball- und ähnliche Sportschuhe | Exchangeable stud consisting of several leather discs fixed to a base plate by means of metal pins; easy replacement of worn discs |

| US 1,797,668 A | 1929 | Bottom For Football Shoes | Sole with socket members for exchangeable studs |

| DE-PS 443 311 | 1925 | Stollen für Fußball- und ähnliche Sportschuhe | Sole with affixed, easily exchangeable leather strips bearing sockets for fastening studs. The studs are composed of several leather discs for adjustable height. |

3.3. Stud material and stud shape

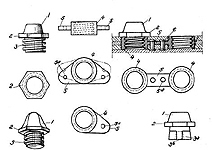

In the middle of 20th century, a large variety of different stud shapes and materials were proposed to improve grip on different surfaces. At the same time, inventions related to improved stability of the fastening and the development of special threads and spanners.

The development of tough and easy to process special plastic materials allowed to produce studs with hard plastic coatings from the late 1970s onwards. Due to these coatings, abrasion did not produce sharp edges so that the risk of injuries caused by worn studs was considerably reduced. Meanwhile, highly abrasion-resistant studs have been developed. Ceramic materials were found to be specifically wear resistant.

Until the end of the 20th century, studs and nubs used on football shoes almost always had a cylindrical or truncated cone shape with circular cross-section. Patent literature, however, contained a number of proposals for enhancing the sole traction by using studs, nubs or other components with elliptical or hoof-shaped ground-engaging surfaces.

Mainly the latter became more and more popular in the past five to ten years. When they were being used for playing athletic professional football, however, it was found that the elliptical shapes were not problem-free. A conspicuous increase in knee injuries, mainly cruciate ligament injuries, has been observed lately during the summer months. It is therefore assumed that the strong grip of elliptical nubs might cause extreme torsional stress to the knee on dry or stiff turf soils.

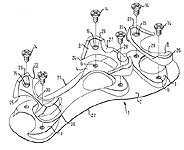

![]() Figure 8b: Sole with threaded inserts, mounted with horse-shoe shaped traction elements (DE 201 22 231 U1)

Figure 8b: Sole with threaded inserts, mounted with horse-shoe shaped traction elements (DE 201 22 231 U1)

Even if lack of fitness of players, not up to the high stress of modern football, has been discussed as a possible cause of injuries, measures have been implemented to better adapt the shoe grip to the pitch conditions. For this purpose, a sole has been developed recently that allows to exchange conventional round studs for horse-shoe or U-shaped traction elements (Figure 8). It was also proposed to mount the studs on rotatable fitting parts in order to reduce shear stress at the knees. It was also proposed to incorporate cushioning elements in the stud threads or to mount the studs on rotatable fitting parts in order to reduce shear stress at knees and foot joints.

To this day, more work is being done on the studs and their interchangeability. The invention DE 10296111 B4 is designed to make changing and removing the cleats particularly easy.

A stud changing system with rotary bayonet lock and torque limitation describes DE 202014003299 U1.

DE 202012013478 U1 promises "traction-optimised stud construction", which presents a "medial rotary traction element".

DE 102015211927 A1 is also intended to improve traction: These are variable, direction-dependent cleats. These should make it possible to change the direction of maximum traction of sports shoes in order to adapt the shoe to the different positions on the pitch where the footballer plays. The idea is that a goalkeeper, for example, needs a different cleat setting than a left wing, etc.

One of the goals of DE 102016211118 is to improve grip, where a function-oriented sole design was developed to improve traction and reduce susceptibility to injury.

The principle of a hanging spike arrangement at the heel promises more flexibility and slip resistance at the same time: in addition to the normal studs at the forefoot, this football shoe has a flexible traction element in the rear foot area (EP 3262963 A1).

| Publication number | Year | Title | Brief description |

|---|---|---|---|

| DE 201 22 231 U1 | 2001 | Sportschuh | Sports shoe featuring sole with threaded inserts for mounting interchangeable sets of studs or horse-shoe shaped traction elements |

| DE 92 14 782 U1 | 1994 | Sportschuh mit einer Laufsohle mit Halterungseinsätzen zur Halterung von Greifelementen | Stud threads with cushioning elements for absorbing lateral forces acting on the foot joints |

| DE 37 03 932 A1 | 1987 | Laufsohle für Sportschuhe, insbesondere Fußballschuhe | Sole with nubs in elliptic shape, arranged along the sole rim in running direction, and vertically thereto in the middle area of the forefoot |

| DE 32 33 900 A1 | 1982 | Sportschuhsohle mit Greifelementen | Light and wear resistant studs made of oxide ceramics |

| DE 26 45 963 A1 | 1976 | Stollen für Fußballschuhe, insbesondere Fußballschuhe | Studs made of polyamide or light metal coated with wear resistant tough plastic material |

| DE-OS 1 685 709 | 1967 | Sport-, insbesondere Fußballschuh | Sole with ribs as traction elements in circular arrangement, for low rotational traction |

| DE-OS 1 685 246 | 1966 | Sportschuh | Sole with studs attached to a pivoting plate, in the forefoot area, in order to minimise rotational traction and the resulting risk of injuries |

| DE-GM 1 899 352 | 1964 | Sportschuh mit an der Laufsohle vorzugsweise auswechselbar angeordneten Stollen | Screw studs made of india-rubber or soft plastic material with centre cavity, open to the bottom side, providing strong grip similar to suction cups |

| US 3,127,687 | 1961 | Athletic Shoe | Football or baseball shoes with elliptical cleats and arcuate shaped traction elements |

| DE-GM 1 739 415 | 1956 | Schraubstollenschlüssel | Screw stud spanner for conical leather or rubber studs |

| AT-PS 195 802 | 1955 | Einrichtung zum Befestigen von Klötzchen oder Dornen an Sportschuhen | Stainless thread socket for screw studs mounted on nylon fastening plate |

| DE-PS 1 031 182 | 1955 | Sportschuh, insbesondere Rennschuh oder Fußballstiefel | Stud sole with thread sockets made of polyamide reinforced by metal inlays |

| DE-PS 961 153 | 1955 | Halter für aufschraubbare Beschlagteile von Sportschuhen | Removable insert for easy thread exchange in screw stud soles |

| DE-GM 1 693 021 | 1954 | Schraubstollen für Sportschuhe | Screw stud with internal plate for thread bolt and pins to prevent plate torsion |

3.4. The development of light and stable outsoles

Outsoles which had mostly been made of hard leather until the middle of the 1950s underwent dramatic changes due to the development of plastic materials such as polyamides. Whereas leather soles, just like leather footballs, take up water on wet surfaces, the utilisation of polyamides allows to produce soles that remain lightweight under all weather conditions.

Use of lighter materials for the uppers and soles of shoes increased the players' speed. This in turn increased demand for ever more stable sole material. The enormous shear forces acting upon the sole in the course of the increasingly athletic football game regularly caused ruptures, vertically to the longitudinal axis of the sole, specifically in cold weather.

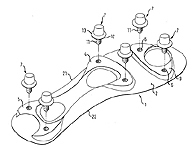

In order to cope with these inconveniences, reinforcing elements and resilient moulded bodies with specifically developed and often highly complex structures have been incorporated in the outsole. These bodies confer springy elastic properties to the sole and enhance heel-to-toe roll motion of the foot during running and kicking.

A modular shoe with studs was developed recently that can be tailored to the biomechanical requirements or aesthetic preferences of the user. It features a specifically adaptable chassis with regard to elastic properties and shape, which is inserted into a shoe upper and fastened by screwing in studs on the lower side of the sole.

To optimise individual foot adaptation, DE 102015208763 A1 features an adjustable upper shoe part and sole.

Knitting techniques are increasingly used today for football shoes, even on the sole: US 020160206039 A1 describes a shoe in which the sole is also knitted (see also US 02016020606046 A1).

In a lawn sport, parts of the ground can get caught between the studs and the grip of the shoe decreases. An additional element between the cleats should prevent such impurities (WO 002016164302 A1, see also WO 002015073631 A1 and DE 202015006061 U1).

Meanwhile, not only the upper material of a football shoe, but also the sole is optimized for ball control: DE 102015202169 A1 describes a shoe with circulating friction elements for better ball control.

In the "shoe with reinforced shot plate", the sole should have direction-optimised flexible properties (EP 000003114958 A1).

| Publication number | Year | Title | Brief description |

|---|---|---|---|

| DE 10 2004 011 680 A1 | 2005 | Stollenschuh | Modular shoe with studs and individually adaptable chassis inlay |

| US 2004/0000075 A1 | 2004 | Article of Cleated Footwear having Medial and Lateral Sides with Differing Properties | Sole with different mechanical properties in the lateral and medial areas of the sole to enhance stability and reduce shear stress |

| DE 692 03 554 T2 | 1992 | Profilierte Sohle für Athletikschuhe | Stable outsole with incorporated plastic plate for stabilising the foot and for cushioning purposes (translation of European Patent specification EP 0 553 570 B1) |

| DE 33 05 160 A1 | 1983 | Sportschuh mit einer federelastischen Laufsohle aus Kunststoff | Stud shoe with springy-elastic sole made of polyamide having an undulating structure in the ball and joint areas for increased flexibility |

| DE 28 47 152 C2 | 1978 | Sportschuhsohle, insbesondere für Fußballschuhe | Polyamide sole with slot-like apertures in the ball area to prevent bending rupture |

| DE-GM 1 885 452 | 1963 | Fußballschuh | Outsole with moulded nylon plate bearing reinforcing ribs for even distribution of pressure and stabilisation of the midfoot area (analogue reinforcing ribs are also contained in patent documents DE 1 918 613, DE 1 973 891 und DE 2 257 965) |

| DE-GM 1 807 406 | 1959 | Allzweck-Sportschuh mit Gummi- bzw. Kunststoffsohle | Light trainer with rubber sole and rubber nubs |

| DE-GM 1 776 337 | 1957 | Sportschuh, insbesondere Rennschuh oder Fußballstiefel | Plastic sole with protective leather layer covering sharp edges to reduce risk of injuries |