Football Footwear

4. Measures for enhancing shooting technique: inlays and structured upper surfaces

4.1. Additional shoe components

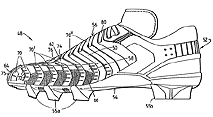

![]() Figure 9: Football shoe with additional weight (20) incorporated in the forefoot sole for stabilising the foot when shooting (DE 103 10 526 B4)

Figure 9: Football shoe with additional weight (20) incorporated in the forefoot sole for stabilising the foot when shooting (DE 103 10 526 B4)

Measures for enhancing the technical skills of players, above all, their ball handling, shooting power and accuracy, have been proposed since the early days of football footwear. The first measure was the previously presented toe cap made of hard leather, which was used as early as the first half of the 19th century to increase the shooting power. Even patent documents from the 20th century contain various toe cap proposals.

In a recent example, additional weights are incorporated in the forefoot area of the sole for stabilising the foot against the torque which is effective when shooting a ball. This allows to lower the power required for stabilising the motion process involved when shooting (Figure 9). A similar effect can be achieved by using inlays with anisotropic bending properties that will become either softer or more rigid, depending on the direction of the rotation of the foot movement. This enhances the shooting power and provides, at the same time, for a pleasant running feeling.

More recent applications are dedicated to the heel area: EP 3123886 A1 describes an "adaptive ultra-light shoe attachment part" and "heel stabilization element".

Hard work is also being done on the further development of socks and socks:

DE 102016207387 A1 describes a special sock-shoe combination "to optimise the contact characteristics". Socks with increased grip promises US 2015/0 264 995 A1.

And to prevent players who have to wait on the bench from getting cold feet in their thin, lightweight football shoes, a "warming overshoe" was invented that is easy to pull over (DE 102009033142).

| Publication number | Year | Title | Brief description |

|---|---|---|---|

| DE 102 50 330 A1 | 2004 | Biegeelement mit drehsinnabhängigem Verhalten | Inlay components with anisotropic bending properties for enhanced shooting power and pleasant running feeling |

| DE 103 10 526 B4 | 2003 | Fußballschuh | Football shoe with additional weight incorporated in the forefoot sole for stabilising the foot when shooting the ball |

| DE-PS 940 962 | 1954 | Schussverstärker für Fußballschuhe | Wedge-shaped instep part for increasing shooting power, arranged in such a way that it is made easier to put the shoe on |

| DE-PS 924 425 | 1953 | Fußballschuh | Football shoe with concave tip for increasing shooting power and scoring accuracy |

| DE-PS 922 572 | 1952 | Fußballschuh | Football half-boot with cork instep plate to protect the foot and enhance shooting technique (cf. section 2.2) |

| DE-PS 910 395 | 1949 | Schußverstärker für Fußballschuhe und mit diesem ausgestatteter Fußballschuh | Component provided on the shoe surface above the instep area for increasing shooting power |

| DE-PS 449 911 | 1926 | Fußballstiefel u. dgl. | Outer toe cap for increasing shooting power, made of resilient material for reducing risk of injuries and improving stability |

| DE-PS 349 241 | 1921 | Spannhalter für Fußballspieler | Instep support straps for tighter fit of the shoe and tougher shots |

4.2. Surface structure

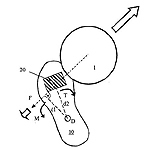

![]() Figure 10a: Early example of structured upper of a football shoe: two beads provided on the instep for improved shooting accuracy (DE-PS 347117)

Figure 10a: Early example of structured upper of a football shoe: two beads provided on the instep for improved shooting accuracy (DE-PS 347117)

Shoe designers realised at an early stage that the surface of the upper may contribute to enhancing the player's ball control. If the upper surface has a suitable structure, the ball will not so easily slide off wet shoes. In an early example, two beads were provided on the instep area, for the ball to find a "rest" in between (Figure 10a).

It was soon proposed to roughen the upper surface or to use materials with high roughness such as crêpe rubber for coating the upper in order to improve the adhesion of the ball.

A very original concept related initially to the use of a natural material, the skin of a cartilaginous fish, on the upper surface (Figures 10b - 10d). This skin consists of very tough tooth-like scales and is virtually wear-proof (DE 1 998 909 U).

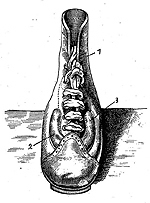

![]() Figure 10b: Later variation: flat strips (3, 4) with scaled surface made of fish skin or synthetic material (from DE 1 930 092 A1)

Figure 10b: Later variation: flat strips (3, 4) with scaled surface made of fish skin or synthetic material (from DE 1 930 092 A1)

Even if this utility model document proposes to use shark skin as an alternative, the concept is unlikely to be suitable for mass production. Consequently, a patent application directly based on this utility model document suggested to alternatively use synthetic replacement materials (DE 1 930 092 A1), simulating the properties of fish skin.

In order to increase the friction on the surface of the shoes, an attachment (DE 102011055261 A1) or an overshoe (EP 000002319341 A1) have recently been developed.

Work also continues on the shoe upper to create "zones optimized for specific areas" (DE 102011086742 A1, DE 102012207300 A1).

Recently, a ball control insert was also proposed as an "optimising insert for the forefoot area" (EP 000002374365 A1) and new ways of surface optimisation (DE 112015000234 T5, EP 000003219217 A1).

US 020170071290 by the leading American sports goods manufacturer describes a football shoe whose knitted upper is provided with additional ball control structures.

DE 10201515219636 A1, registered by Germany's largest competitor, defines a manufacturing process for coating a fabric with a three-dimensional shape whose special functional coating should have advantages for ball guidance.

High-quality synthetic materials have been of great importance in this field too. They allowed to develop ever more sophisticated surfaces for the instep, tip, sides and heel areas featuring tailor-made materials properties and complex structures.

The structural concept, copied from nature, of arranging scale-like ribs on the shoe surface has meanwhile been optimised using synthetic materials (Figure 11).

| Publication number | Year | Title | Brief description |

|---|---|---|---|

| US 6,523,282 B1 | 2003 | Article of Footwear for Gripping and Kicking the Ball | Further development of a structured outer surface of a shoe upper with fin or spike shaped protrusions |

| WO 92/22224 A1 | 1991 | Football Boot | Football shoe whose surface is provided with individual scale-like or rib-like structure elements for improved ball adhesion |

| DE 28 12 760 A1 | 1978 | Sportschuh, insbesondere Fußballschuh | Net layer incorporated in the upper; its relief shows through the thin outer skin of the shoe to obtain a structured surface |

| DE-OS 1 930 092 | 1969 | Sportschuh mit besonders griffiger Schaftaußenseite, insbesondere Fußballschuh | Plastic coating with good grip that copies the scale-like structure of fish skin |

| DE-GM 1 998 909 | 1968 | Fußballschuh | Shoe surface coated with the skin of a cartilaginous fish whose scale structure allows to obtain a particularly good ball adhesion |

| DE-GM 1 899 722 | 1964 | Fußballschuh | Specifically shaped heel cap for improving the ball feeling |

| DE-OS 1 149 273 | 1961 | Fußballstiefel mit griffiger Schaftoberfläche | Ornamental upper surface with perforated coating, whose apertures are filled with plastic material |

| DE-GM 1 805 045 | 1959 | Fußballstiefel | Surface structuring by means of roughened rubber pads affixed to the shoe instep and tip |

| DE-GM 1 791 938 | 1959 | Fußballschuh | Roughening of the outside leather upper of the shoe for better ball adhesion |

| DE-PS 822 799 | 1950 | Fußballstiefel | For improving ball adhesion, the front part of the shoe upper is made of a material such as crêpe rubber which has a high friction value in comparison to leather |

| DE-PS 347 117 | 1921 | Fußballstiefel | Beads provided on the instep area of the shoe to improve shooting accuracy |

4.3. The lacing

Tension bands devices such as straps incorporated in the football boot were proposed as early as in the 1920s for supporting the foot when kicking the ball. Subsequent improvements of the lacing were mainly intended to enhance the shoe fit (ao. by means of lacing in the heels area), to make stepping-in more comfortable or to obtain a specific fit, eg. for injured, bandaged ankles.

The concept of tension lacing - further developed in a suitable manner - is still being applied in modern football shoes (EP 0 877 566). It should create a tight and comfortable fit of the shoe and prevent fatigue of the musculoskeletal system.

In connection with efforts to optimise shoe surfaces for improved ball adhesion, most of today's developments focus on flat adhesion of the shoe surface to the foot. At the same time, interference of the laces is being eliminated either by means of side lacing or special lace covers, such as tongues or concave cover attachments.

The latest application was for a tension band to be applied to a closed sports shoe, which is intended to improve the fit of the sports shoe to the wearer's foot and increase ball control (DE 202014004188 U1).

DE 102016215263 A1 does without lacing and describes a shoe uppers made of braided materials "for selective elastic adjustment".

| Publication number | Year | Title | Brief description |

|---|---|---|---|

| WO 2007/020483 A1 | 2007 | Lacing for Sport Shoes and a Sport Shoe with such a Lacing | Football shoe with V-shaped lacing slots on either side for enlarging the shoe opening |

| WO 99/26503 A1 | 1998 | Sporting Footwear | Concave instep attachment covering the lacing, for improved ball handling |

| EP 0 877 566 B1 | 1997 | Sportschuh, insbesondere Fußballschuh | Football shoe with tension strips for stiffening purposes and improved shoe fit |

| DE-GM 92 14 715 | 1992 | Schuh mit Zentralverschluß | Rear-entry football shoe for lace-free design of the instep area (corresponds to EP 0 666 718 B1) |

| DE-OS 2 208 110 | 1972 | Sporthalbschuh, insbesondere Fußballhalbschuh | Football shoe with side fastening strap for adapting the upper width, eg. to accommodate bandaged ankles |

| CH-PS 532 374 | 1970 | Fussballschuh | Football shoe with side lacing (compare DD 89 796) |

| DE-OS 1 947 823 | 1969 | Schuhwerk, insbesondere Fußballschuh oder Fußballstiefel | Leather tongue covered lacing for improved ball control |

| DE-GM 1 849 642 | 1962 | Sportschuh, insbesondere Fußballschuh | Football shoe with lace holders for guiding the lace around the ankle area |

| DE-PS 930 859 | 1952 | Fußballschuh | Football shoe with additional straps at the mid-foot area for tighter fastening of the shoe |

| DE-PS 349 241 | 1921 | Spannhalter für Fußballspieler | Instep support straps for tighter fit of the shoe and tougher shots |